Page content

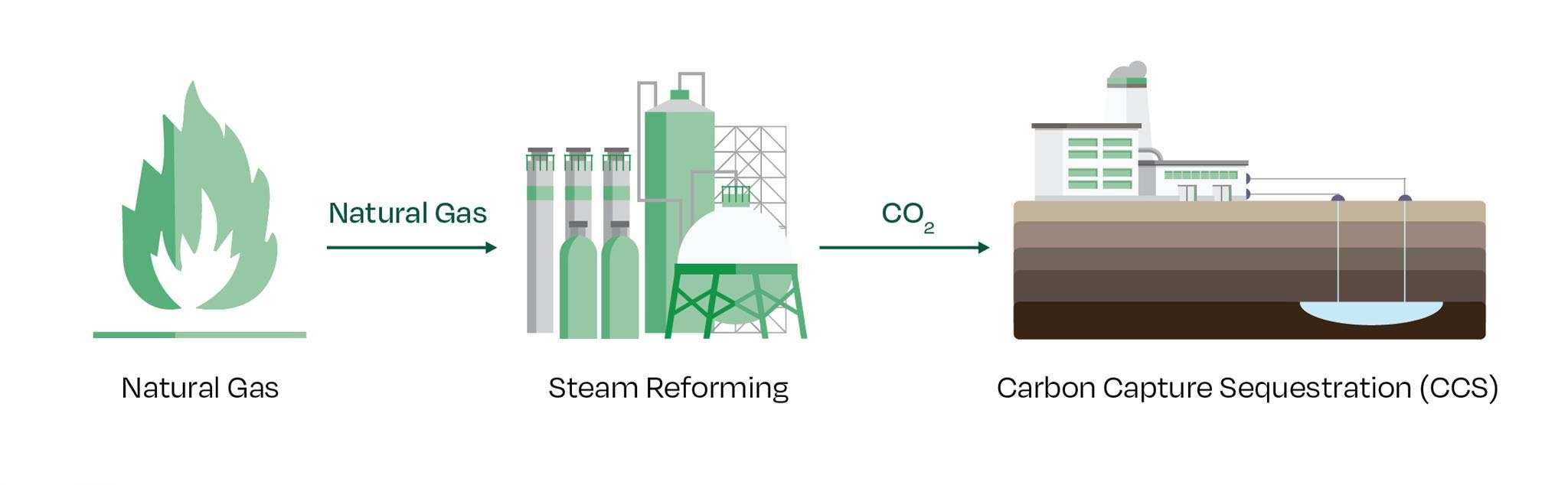

CCS requires a three-step process

How Carbon Capture and Sequestration Works

The approved projects will focus on purifying and compressing (step 2) captured CO2 to enable transportation to sequestration sites. We will construct units at the Donaldsonville and Yazoo City complexes that dehydrate and compress CO2, a process essential for CO2 transport via pipeline to sequestration sites. Management expects that, once the units are in service and sequestration is initiated, the Company could sequester up to 2.5 million tons of CO2 per year (2 million tons at Donaldsonville and 500,000 tons at Yazoo City). The Company is currently in advanced discussions with several parties regarding transportation and sequestration of CO2 from these projects.

The Company has committed $285 million in capital to the Donaldsonville and Yazoo City projects. Under current regulations, the projects would be expected to qualify for tax credits under Section 45Q of the Internal Revenue Code, which provides a credit per metric ton of CO2 sequestered.

Because we have access to potential CCS sites at seven of our nine manufacturing sites, we would expect to pursue additional blue ammonia projects within our network over time. We project that our network can produce approximately 3.5 million tons of blue ammonia per year without affecting our current ability to supply nitrogen fertilizers given that products such as urea require CO2 to be produced.

We also will enable the production of blue ammonia through certified carbon abatement projects that fully eliminate carbon emissions. These projects will generate certified carbon credits that we can use to offset carbon emissions from conventional ammonia production or sell to other market participants looking for carbon offsets.

Additionally, we are beginning to analyze the potential use of blue ammonia to drive value chain decarbonization across multiple sectors, globally, as demonstrated in our collaborations with industry leaders such as Mitsui and Itochu.